_ Philip Martin, professor emeritus, University of California. 1 February 2024.*

Mechanizing fruit and vegetable production

The U.S. has had about 2.5 million hired farm workers since the Immigration Reform and Control Act of 1986 (IRCA) legalized 1.1 million unauthorized farm workers and made it easier for farm employers to hire legal H-2A guestworkers. IRCA supporters promised that legalized and empowered farm workers would demand higher wages, and that farm employers would have to raise wages and improve working conditions in order to retain legalized workers or hire H-2A guestworkers.

IRCA was a case of good intentions gone awry (Martin, 1994). The Special Agricultural Worker (SAW) program was riddled with fraud, in part because unauthorized foreigners could buy proof of 90 days of farm work from corrupt labor contractors and others, and the U.S. government did not detect these applicants. The use of false documents to obtain legal status spread to newly arrived unauthorized foreigners, and Mexican-born farm workers soon spread throughout U.S. agriculture. Since the mid-1990s, half of the workers employed on U.S. crop farms have been unauthorized.

The Farm Workforce Modernization Act approved by the House in March 2021 would repeat the agricultural grand bargain at the heart of IRCA, viz, legalization for unauthorized farm workers in exchange for easier access to H-2A guestworkers. As background for debates over the FWMA, this report explains the options to replace U.S. farm workers with machines, H-2A guestworkers, and imports.

Farm Labor Costs

Agriculture often provides textbook examples of competitive markets in action. Many farmers produce the same corn or wheat whose price is determined by supply and demand, just as farm wages reflect the interaction of the supply of farm workers and the demand for them. Farmers plant crops and trees and expect workers to be available when they are needed, and there have normally been enough workers willing to fill seasonal jobs to keep farm wages near the bottom of the U.S. wage hierarchy.

When farm wages and labor costs rise, farmers substitute machines for workers. Congress debated ending the Bracero program for several years before the last Braceros were admitted in 1964, but farmers were nonetheless surprised when the program ended, making 1965 a year of transition to higher farm wages. Farm adjustments included the mechanization of the processing tomato harvest, the commodity that employed the most Braceros in the early 1960s. Other commodities switched from handling 50- to 60-pound lugs of fresh produce by hand to dumping fruit into 1,000-pound bins handled by forklifts, eliminating jobs. Union activities won the United Farm Workers union a 40 percent one-year wage increase in 1966 that raised the wages of table grape harvesters from $1.25 to $1.75 an hour.

The end of the Bracero program, rising wages, and union activities prompted many public and private efforts to develop labor-saving farm machines. A three-volume study commissioned by the U.S. Department of Labor concluded that most of these efforts would be successful, so there would be no need for seasonal farm workers within a decade. Researchers urged the U.S. government to create education and training programs to prepare farm workers soon to be displaced for nonfarm jobs (Cargill and Rossmiller, 1970).

Labor-saving mechanization research shriveled in the 1970s as the supply of farm workers increased and lawsuits challenged the use of public funds to develop machines that could reduce jobs for farm workers. With ever-more unauthorized Mexicans arriving after peso devaluations and a rising demand for fresh fruits and vegetables, farmers planted more labor-intensive commodities and found an ample supply of seasonal workers among U.S. workers and newly arrived and unauthorized Mexicans.

By the early 1980s, unauthorized Mexicans were concentrated in a few California commodities and were less than a quarter of farm workers (Mines and Martin, 1983). IRCA aimed to prevent the share of unauthorized farm workers from increasing by fining employers who knowingly hired unauthorized workers. However, employer sanctions failed to slow the influx of unauthorized Mexicans, and continued illegal immigration provided ample supplies of farm labor until the 2008-09 recession, keeping average hourly farm earnings at about half the level of nonfarm earnings.

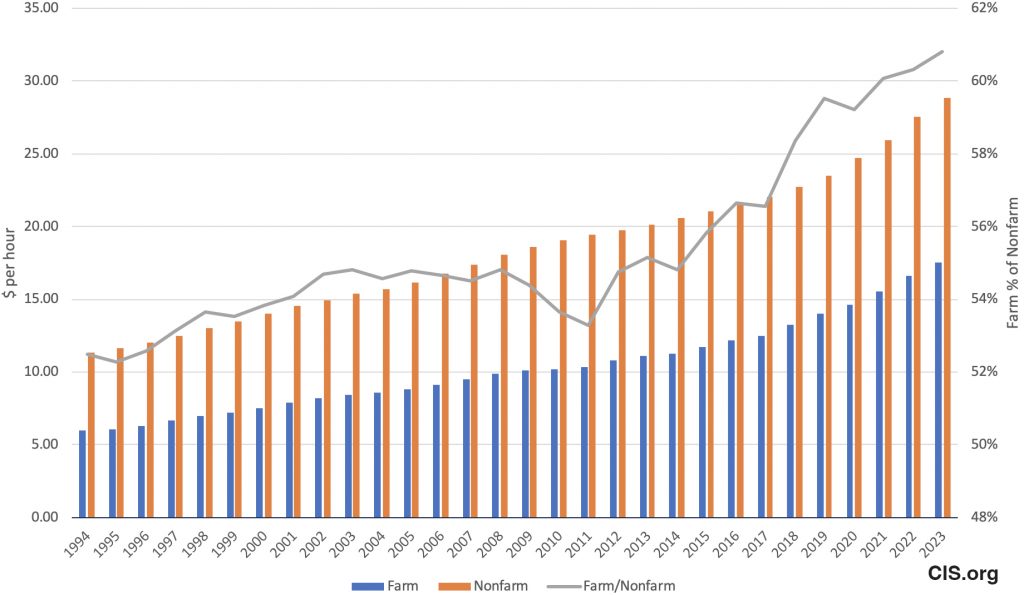

The slowdown in unauthorized Mexico-U.S. migration over the past decade, rising state minimum wages, and increased demands for fresh fruits and vegetables combined to put upward pressure on farm labor costs in recent years. The real or inflation-adjusted average hourly earnings of farm workers have been increasing faster than the earnings of nonfarm workers, up 16 percent to $13.99 an hour in 2019 versus $23.51 of nonfarm workers, bringing farm wages to almost 60 percent of nonfarm earnings.

Figure 1. Farm and Nonfarm Average Hourly Earnings, 1994-2023

Sources: “Farm Labor”, USDA; “Current Employment Statistics – CES (National)”, Bureau of Labor Statistics.

Mechanization

Human history is the story of productivity improvements in agriculture that allowed fewer farmers to feed more people, setting the stage for the emergence of cities and ruling elites. Today, farmers mechanize tasks when the cost of machine services is cheaper than hand labor.

Most of the commodities that remain hand-harvested are fresh fruits and vegetables. Farms producing fruits and nuts, vegetables and melons, and horticultural specialty farms that include nurseries and greenhouses (FVH) are a sixth of U.S. farm employers, but they accounted for half of farm labor expenditures in 2017. Within this FVH sector, a handful of commodities employ most U.S. farm workers, including apples, oranges, strawberries, lettuce, and tomatoes.

Mechanizing the tasks done by hand workers in fresh fruits and vegetables is hard because much of the work is outdoors and in unpredictable settings. There are two general rules about harvest mechanization: Once-over is easier than selective harvesting, and crops that are processed are easier to mechanize than those that are sold fresh (Vougioukas, 2019).

Once-over harvesting is easiest for machines. Most vegetables are annual plants, so the machine can cut the plant and use shakers and sorters to isolate the desired vegetables. Root vegetables such as potatoes are harvested by machines that pass through the field one time and dig the crop from the soil, remove the dirt, and convey the harvested crop to a truck or wagon. Machines harvest fruit from trees and vines in several ways. Catch-and-shake machines use rubber-coated heads that grasp the trunk or limb and deliver a jolt to dislodge the fruit into a catching frame before it is conveyed to trucks or bins, as with oranges and peaches. Wine grapes and blueberries are harvested by machines that pass over the row and use rotating fingers to dislodge the fruit onto conveyor belts.

Selective harvesting requires machines to distinguish ripe and unripe fruit and vegetables and select only those that are ripe. Humans are much better than machines at locating an apple, determining its maturity, and harvesting it without damaging the picked apple and nearby immature apples. Machines to selectively harvest apples are in development, but they require farmers to replant orchards to make the apples more visible. To be competitive, the machines have to pick faster than humans.

The second rule is that it is easier to mechanize commodities destined for processing than those sold fresh to consumers. Processors are less concerned about blemishes and other damage that may occur in machine picking, which explains why most vegetables that are canned or frozen, such as beans, corn, and peas, are harvested by machine. However, preferences for fresh rather than processed fruits and vegetables has slowed harvest mechanization.

Accelerating farm mechanization requires a systems perspective, cooperation between researchers in biology and engineering, and trial-and-error refinements. The systems perspective highlights the fact that machines rarely replace workers in a seamless fashion. Instead, the entire farm-to-consumer supply chain may require changes. For example, farmers may have to plant new varieties in new ways that facilitate the use of machines, packers and processors must adjust to handle machine-harvested produce, and consumers must accept machine-handled fruits and vegetables.

The key to labor-saving mechanization is cooperation between scientists and engineers. Plant scientists must often modify plants so that fruits and vegetables ripen uniformly, which allows engineers to develop once-over harvesting systems. Many commodities that are hand-harvested are picked multiple times, including apples, head lettuce, and strawberries. Mechanizing these harvests requires an assessment of whether it is easier to develop plants whose fruits or vegetables ripen uniformly or to develop a machine that can select only ripe produce.

The third feature of labor-saving mechanization is refining labor-saving machines in a trial-and-error process. The first machines rarely function as expected under field conditions, so that successfully mechanizing a farm activity is more of a process than an event. The process of perfecting machines is time-consuming and can be costly, since farmers must pay for machines that may not work, leaving them with the cost of the machine and wages for hand workers.

These hurdles were overcome to transform the California processing tomato harvest in the 1960s. Picking the tomatoes used to make ketchup and tomato paste employed more Braceros than any other commodity in the early 1960s, and congressional testimony asserted that, without Braceros, ketchup would become a luxury.

Processing tomato mechanization required many changes. First, plant scientists developed tomatoes that ripened uniformly and had an oblong shape that could withstand machine handling better than round tomatoes. Second, engineers developed machines to cut tomato plants, shake off the tomatoes, and convey them to trucks traveling alongside the harvester. Third, processing plants adapted to accept tomatoes by the 12.5-ton truckload rather than 50-pound lugs. Finally, farmers specialized in growing tomatoes to justify their investment in machines to harvest them, transforming tomato farming from thousands of farmers each with a few acres to hundreds of farmers each with hundreds of acres.

What would be required to repeat the processing tomato story for other fruits and vegetables? The major economic drivers of tomato harvest mechanization were no more Braceros and higher labor costs, but the key ingredients for mechanization included basic and applied university research and government and industry cooperation to accelerate the adoption of machines.

For example, farmers are paid by weight, and at current prices of about $80 a ton or four cents a pound, a 50-pound lug would be worth $2 while a 12.5-ton load is worth $1,000. Farmers may not object strenuously if processors reject a lug of tomatoes, but they may protest the rejection of a truckload. Government-run (later privatized) stations that took random samples of tomatoes resolved an issue that could have slowed mechanization.

The Adjustment Spectrum

A close look at four major fruits and three vegetables reveals a spectrum of potential adjustments to higher labor costs. At one end are commodities that are embracing more labor-saving mechanization, such as blueberries and raisin and wine grapes. At the other end are commodities that are hiring more H-2A guestworkers to continue hand harvesting, such as iceberg lettuce, melons, tomatoes, strawberries, and table grapes. Looming over some commodities, including blueberries, raisins, melons, tomatoes, and table grapes, are rising volumes of low-cost imports.

Blueberries and Grapes

Blueberries, raisin grapes, and wine grapes are at the labor-saving mechanization end of the spectrum. Machines are available to harvest these commodities, and rising imports hold down grower prices and encourage mechanization to reduce labor costs.

Challenges to mechanizing blueberries include the up-front investment of $200,000 to $300,000 for a machine and the lower pack-outs of marketable fresh blueberries because machines harvest more immature fruit than hand pickers. Farmers receive about $2 a pound for fresh blueberries, but less than $1 a pound for blueberries that are frozen or used as food ingredients. Hand-picking blueberries typically costs $0.50 a pound, while picking by machine costs $0.20 or less. Most farmers want to sell their berries fresh to consumers, so many hand-pick blueberries even though some wind up being processed. More accurate forecasting of the destination of blueberries, as well as better-padded machines to minimize damage to harvested berries, could accelerate harvest mechanization.

Raisin and wine grape mechanization require up-front investments to restructure vineyards so that machines can harvest efficiently. Machines harvest a third of California raisins and 90 percent of California’s wine grapes. Raisin grape mechanization is slowed by the characteristics of growers, many of whom are over 60 and who have small vineyards, as well as rising imports of lower-cost raisins from Turkey. Instead of investing in new grape varieties and trellising systems to use machines in their vineyards, many raisin growers are switching to mechanized almonds.

Lettuce, Strawberries, and Tomatoes

Table grapes, strawberries, iceberg lettuce, melons, and fresh, open-field tomatoes lie near the continued hand-harvest end of the spectrum. Growers of these commodities are hiring more H-2A guestworkers to replace U.S. workers who are aging out of farm work. Almost all H-2A and unauthorized U.S. farm workers were born in Mexico, but the H-2A workers are a decade younger than the early 40s age of unauthorized workers. With harvesting aids such as conveyor belts, the availability of H-2A workers raises the bar for labor-saving machines to replace hand workers.

Strawberries illustrate the challenge. Demand for fresh berries has been rising with their health benefits, year-round availability, and convenient packaging, making strawberries, blueberries, raspberries, and blackberries the highest value fresh produce item sold in U.S. supermarkets. Strawberries account for over half of the $8 billion a year in consumer berry spending.

Strawberries are picked by workers who push a light wheelbarrow containing the plastic clamshells in which strawberries are sold between two adjacent elevated rows, picking from both rows into the clamshells. Workers are paid piece-rate wages of $2 per flat of 12 12-once pints or eight one-pound clamshells, and are guaranteed at least the California minimum wage of $14 an hour in 2021. Most workers pick 10 flats an hour and earn $14 to $16.

A conveyor belt traveling in front of strawberry pickers reduces walking time, enabling workers to pick more flats. Conveyor belts cost over $100,000 each, and function best in the large and flat fields of southern California. There have been disputes over how much employers can lower piece-rate wages if they provide conveyor belts, which has slowed their spread in northern California strawberry fields.

Machines are being developed to harvest strawberries, but using them requires a significant up-front investment in new farming techniques, including training strawberries to grow over the edges of hardened rows so that machines can more easily find and pick them. These technical challenges mean that most strawberries will be hand-picked for the next decade, but a rising share may come from Mexico, which has a fast-expanding strawberry industry that exports all types of fresh berries to the U.S.

Table grapes, melons, and tomatoes face similar challenges to mechanization. Their characteristics make it hard for machines to locate and harvest them quickly without damage. Rising imports put downward pressure on U.S. grower prices, which makes farmers reluctant to undertake risky investments in machines. The U.S. production of cantaloupes and open-field fresh tomatoes is likely to continue to shrink in the face of rising imports and decreased consumer demand, while table grape growers are likely to adopt mechanical aids to make hand workers more productive.

Apples

Apples are between the mechanization and hand-labor ends of the spectrum. New varieties such as Cosmic Crisp and Honeycrisp are planted so that the tree limbs form walls of fruit that are easier for workers or machines to pick. These new varieties generate higher grower prices and require careful handling, which encourages apple growers to hire more H-2A workers and provide them with platforms rather than ladders so that they can pick faster. The U.S. is a net exporter of fresh apples and faces little competition from imported fresh apples.

Apples are picked by workers who climb ladders that lean into trees and pick the fruit from top to bottom into bags or buckets that hang over their shoulders. Full bags of most varieties are dumped into 925-pound bins. Hydraulic platforms that can be raised and lowered are a substitute for ladders that increase worker productivity, enabling a crew of six to eight workers to pick more bins collectively than they could if they individually filled bins by using ladders to pick.

Many varieties of apples ripen uniformly enough for once-over picking, but shake-and-catch machines leave growers with less marketable fruit because some of the falling apples are damaged, so they must be sold in the low-price processing market rather than the higher-price fresh market. Selective apple pickers that imitate humans and pick individual fruit increase the amount of marketable fruit, but are more expensive and complex. Selective harvesting machines work best if apples grow on trellis systems that resemble vineyards so that artificial intelligence can use cameras and LIDAR, or light detection and ranging radar, to find and pick ripe apples.

Conclusions

The U.S. farm workforce of 2.5 million includes two million Mexican-born workers, half of whom are unauthorized. Congress is debating how to deal with unauthorized farm workers, and the FWMA approved by the House in March 2021 would repeat IRCA’s agricultural grand bargain, viz, legalize currently unauthorized farm workers and make it easier for farm employers to hire H-2A guestworkers.

IRCA’s agricultural provisions did not provide the promised legal farm workforce. Instead, unauthorized workers replaced newly legalized workers in the fields, prompting a debate over how to fulfill IRCA’s promise. While Congress debated, the demand for farm workers remained stable, but the slowdown in unauthorized Mexico-U.S. migration after 2008-09 has raised the H-2A share of the farm workforce.

If current trends continue, the H-2A share of the farm workforce, currently about 10 percent, will soon surpass the peak 20 percent Bracero share of U.S. farm workers. Labor-saving mechanization may begin to reduce the demand for farm workers if farm wages increase faster than nonfarm wages, but the major factor reducing the number of U.S. farm workers is rising imports of fresh fruits and vegetables. About 60 percent of U.S. fresh fruit, and 35 percent of fresh vegetables, are imported. Half of the fresh fruit imports and three-fourths of the fresh vegetable imports are from Mexico. A million Mexicans are employed on Mexican farms that export fruits and vegetables to the U.S., compared with two million Mexican-born workers who are employed in U.S. agriculture.

There is a race in U.S. fields between labor-saving machines and migrant H-2A workers playing out amidst rising imports. Higher labor costs accelerate investments in machines to replace workers and spur government and private efforts to develop new farming systems, biological and engineering breakthroughs, and supply chain adjustments to accelerate labor-saving mechanization.

The mechanization of the processing tomato harvest in the 1960s demonstrates the importance of government policies in agricultural mechanization. In that case, the government-subsidized biological and engineering research, coordinated supply chain adjustments to facilitate mechanization, and enacted policies, including ending the Bracero program, which raised farm labor costs. Government policies can slow or speed mechanization in the 21st century by influencing the pace of labor-saving research, the cost of farm workers, and the importance of imports. Research, migration, and trade policies will help to determine whether workers or machines pick U.S. apples and oranges in 2030.

Bibliography

Burton Cargill and George Rossmiller, Fruit and Vegetable Harvest Mechanization: Technological Implications, Rural Manpower Center, Michigan State University, 1969.

Philip Martin, “Good intentions gone awry: IRCA and US agriculture”, The Annals of the Academy of Political and Social Science, Vol 534: 44-57, July 1994.

Richard Mines and Philip Martin, “Foreign workers in selected California crops”, California Agriculture, 1983.

Yoav Sarig, James Thompson, and Galen Brown, “Alternatives to Immigrant Labor?”, Center for Immigration Studies, 2000.

Stavros G. Vougioukas, “Agricultural Robotics”, Annual Review of Control, Robotics, and Autonomous Systems, 2019.

* Republished from the original publication by the Center for Immigration Studies.